Laboratory of a new generation at BelMag

BelMag presented the project "Technology for the creation of structures and production of innovative suspension ball joints and stabilizer links of cars with increased durability for operation in difficult climatic conditions of the Russian Federation" and opened a new test center.

BelMag presented the project "Technology for the creation of structures and production of innovative suspension ball joints and stabilizer links of cars with increased durability for operation in difficult climatic conditions of the Russian Federation" and opened a new test center.

Over the years of work in the production of automotive components, BelMag has determined the following principle – to produce a truly high-quality product, you need to develop it yourself.

Therefore, the company pays special attention to the competence development in automotive components design that meets the requirements of global car manufacturers. As a result of the scientific approach to development – several patents and inventions, the practical value of which can be tracked at various stages of the company development. In the process of creating a new product, BelMag pays attention to each of its components: not only the shape, but also the material, as well as the technologies that are used during production. Before the mass production stage, prototypes are tested to identify and overcome all possible problems in advance, not in the process of using the part on the customer's car.

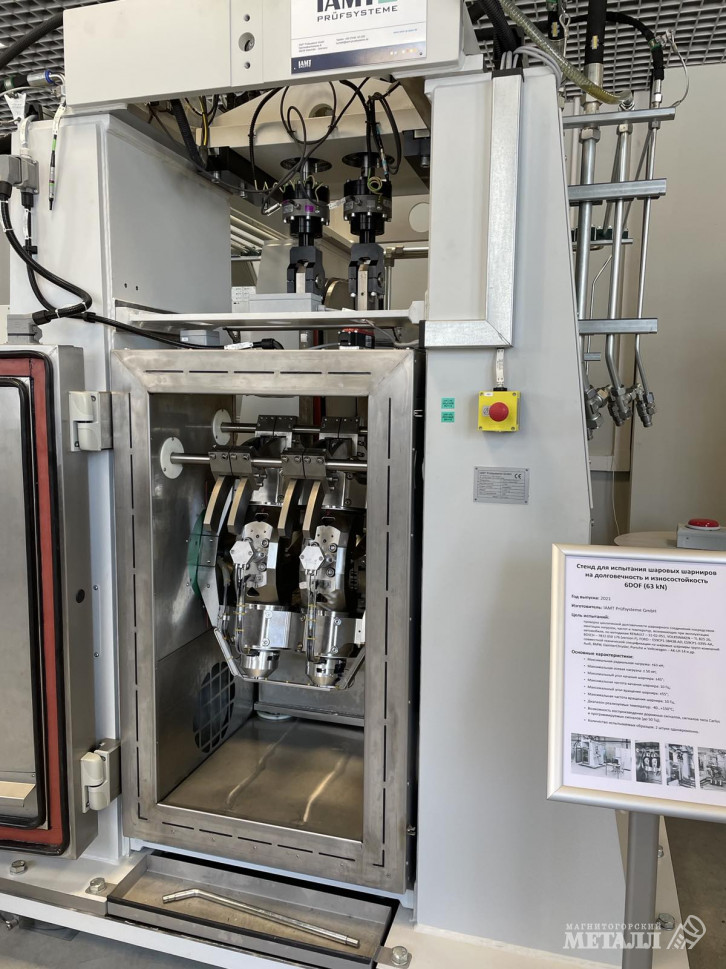

The project has been implemented since January 2021. During this time, there was created new test center and purchased a unique stand that has no analogues in Russia. It allows testing products according to the customers’ requirements, such as Renault, Volkswagen, Ford. The stand allows to load the sample by compressing, loosening in different axes, at temperatures from minus 40 to plus 150 degrees.

After the launch of the stand, the guests were able to see the ball joints of the Lada Vesta SW Cross car when testing. In a short period, the part has passed the entire period of its warranty and post-warranty life and has shown how reliably it is made. When testing there had been created conditions that were as close to real as possible, including physical impacts such as water and dirt.

– The German company IAMT Prüfsysteme GmbH supplied the equipment to BelMag, - said Igor Gun, General Director of JSC NPO BelMag. - In total, 23 stands were made for plants in Korea, Germany, Japan, China. The only one was made for Russia, and it is for BelMag.

Pavel Ryzhiy, Minister of Industry, New Technologies and Natural Resources of the Chelyabinsk Region, congratulated the company's staff on the opening of the new test center:

Pavel Ryzhiy, Minister of Industry, New Technologies and Natural Resources of the Chelyabinsk Region, congratulated the company's staff on the opening of the new test center:

- The launch of the center is a key element in the transition from research activities to the beginning of the industrial phase of the project on design and production of innovative suspension ball joints and stabilizer links of increased durability. It is important for operation in difficult climatic conditions of the country.

The Ministry of Industry and Trade of Russia took a direct part in the implementation of the project. At the beginning of 2021, BelMag's application was approved in a competition conducted by the department for the right to receive subsidies from the federal budget to Russian organizations. Funds were allocated to ensure the costs of research and development work on modern technologies.

BelMag has chosen the right development strategy because the localization that we have in Russia today is focused mainly on the domestic customer," says Andrey Kraynov, General Director of the Machine-building Association Cluster of Automotive Industry. – If we talk about global automakers - Volkswagen, Mercedes, KIA, Toyota, it's not enough for them just to have "hands" – they need a "brain". BelMag possesses it. Today, a large system has been added to this "brain", which will allow to do tests, and not spend significant resources paying for specialists and equipment abroad. This option of accumulating their competencies, in addition to the already existing high-class production – is the only right way for Russian companies today, which will allow them to apply for orders from global manufacturers.

Vitaly Bakhmetiev, State Duma deputy noted that BelMag is a large company in terms of production volumes (the turnover of the plant in 2021 amounted to more than two billion rubles) and in terms of the number of employees. 25 years ago, when production was launched, its plans were not so ambitious. Today, the company supplies automotive components to leading European automobile lines – and it's worth a lot.

– The launched project is not regional, but all-Russian level, - said Vitaly Bakhmetiev. – Foreign manufacturers will not work with suppliers without a guarantee of high quality. Test Center at BelMag is a new generation laboratory, it is a completely new level of company development.

Original is on the website: Магнитогорский металл